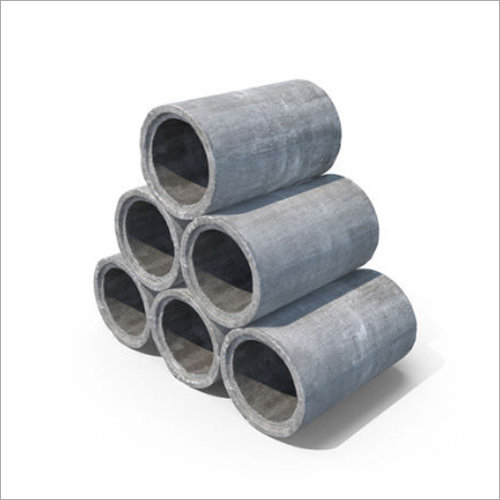

RCC Hume Pipe

RCC Hume Pipe Specification

- Coating Type

- Uncoated

- Tolerance

- 2 mm

- Flexibility

- Rigid

- Tensile Strength

- 250 - 350 kg/cm

- Connection Type

- Socket Type

- Diameter

- 150 mm to 1800 mm (various sizes available)

- Sealing Type

- Rubber Ring

- Temperature Range

- -10C to 60C

- Product Type

- RCC Pipe

- Material

- Other

- Connection

- Bell & Spigot Joint

- Shape

- Cylindrical

- Standard

- IS:458

- Surface Treatment

- Smooth finish

- Outer Diameter

- 300 mm, 450 mm, 600 mm (options available)

- Section Shape

- Round

- Length

- 2-2.5 Meter (m)

- Thickness

- 25 Millimeter (mm)

- Color

- Grey

- Usage

- Drainage, Sewerage, Irrigation

- Rated Pressure

- 2.5 to 4 kg/cm

- Application

- Civil Construction, Water Supply

- Material Grade

- M30/M40 Grade Concrete

- Inner Diameter

- Varies from 120 mm to 1700 mm

- Testing

- Hydrostatic & Load Test as per IS:458

- Load Class

- NP2, NP3, NP4 (as per IS:458)

- Installation

- Below or above ground

- Weight Per Meter

- 85 Kg to 1300 Kg/m (size dependent)

- Life Expectancy

- More than 50 years

- Water Absorption

- 6% (as per IS standard)

- Concrete Mix Ratio

- 1:2:4 (Cement:Sand:Aggregate)

- Jointing Type

- Collar Joint, Flush Joint

- Compressive Strength

- Minimum 25 N/mm

RCC Hume Pipe Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 2-3 Days

- Main Domestic Market

- All India

About RCC Hume Pipe

Our company is engaged in providing a quality assured RCC Hume Pipe. The offered pipe is generally used for water drainage, sewerage, culverts and irrigation. This product is perfect for various hardware industrial applications and able to carry heavy pressure. RCC Hume Pipe is very much preferred for such usage because they are leak proof, are easily repairable and are non-reactive to sewerage toxins. Moreover, this is available in various specifications as per customers choices.

Other Detail

Diameter : 150 mm

Features : Durable

Built to Last in Demanding Conditions

These RCC Hume Pipes boast a lifespan of over 50 years, thanks to high-grade M30/M40 concrete and stringent quality checks. With superior compressive strength, minimal water absorption, and robust surface treatments, they perform reliably under various environmental and load conditions.

Versatile Applications across Industries

Designed for flexibility in use, the pipes are well-suited for drainage, sewerage, irrigation, and water supply. They can be installed either below or above ground, with multiple diameters and pressure ratings to fit specific project needs. Their adaptability makes them a preferred choice in civil construction across India.

Precision Engineering for Efficient Installation

With tolerances as tight as 2 mm and multiple jointing optionsincluding collar, flush, bell, and spigot jointsthe pipes ensure a secure fit and excellent leak resistance. The standardized lengths and shapes simplify handling and streamline the installation process on site.

FAQs of RCC Hume Pipe:

Q: What are the available load classes and how do I choose the right one?

A: RCC Hume Pipes come in load classes NP2, NP3, and NP4 as per IS:458. The choice depends on installation depth, load from surface traffic, and intended usage. For heavier loads or deep installations, NP4 is recommended while NP2 suffices for lighter, shallower applications.Q: How is the installation process carried out for these pipes?

A: Installation involves laying the pipes either below or above ground, using standardized joint types such as collar, flush, or socket (bell & spigot). Sealing is typically done with a rubber ring to ensure watertightness. Pipes are joined and aligned according to site requirements and tested for hydrostatic and load compliance.Q: What benefits do these RCC Hume Pipes provide in civil engineering projects?

A: These pipes offer long-lasting durability, outstanding resistance to loads, minimal maintenance, and excellent performance in both wet and dry conditions. Their high compressive and tensile strength ensures reliability in critical infrastructures like drainage and water supply systems.Q: What testing procedures are performed on these pipes to ensure quality?

A: Each pipe undergoes hydrostatic and load tests as mandated by IS:458, verifying water tightness and structural integrity. Water absorption is checked to ensure it does not exceed 6%, further guaranteeing high performance and longevity under operational conditions.Q: Where are these RCC Hume Pipes typically used?

A: Common applications include drainage systems, sewer lines, irrigation projects, and major water supply networks. Their adaptability makes them suitable for use in roads, highways, culverts, and agricultural or municipal water management structures.Q: What is the typical size range and how do I select the right diameter?

A: RCC Hume Pipes are available with inner diameters from 120 mm to 1700 mm and outer diameters of 300, 450, and 600 mm, among other options. Selection depends on project flow requirements, pipe placement, and hydraulic calculations.Q: How does the concrete grade and mix ratio influence pipe performance?

A: The M30/M40 grade concrete and 1:2:4 mix ratio ensure a strong, dense structure with a minimum compressive strength of 25 N/mm. This provides the necessary robustness to withstand external loads, resist water ingress, and support the longevity of the pipe in demanding applications.

Price 200 INR/ Square Meter

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 2-3 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Pipes Category

Collar Joint RCC Pipe

Price 200 INR / Square Meter

Minimum Order Quantity : 10 Pieces

Length : 22.5 Meter (m)

Material : Other , Cement

Thickness : 25 Millimeter (mm)

Product Type : RCC Pipe, Other

Spun RCC Pipe

Price 200 INR / Square Meter

Minimum Order Quantity : 10 Pieces

Length : 22.5 Meter (m)

Material : Other , Cement

Thickness : 25 Millimeter (mm)

Product Type : Other, RCC Pipe

Flush Joint RCC Pipe

Price 200 INR / Square Meter

Minimum Order Quantity : 10 Pieces

Length : 22.5 Meter (m)

Material : Other

Thickness : 25 Millimeter (mm)

Product Type : Other, RCC Pipe